The AMS VR38 Billet Block is made of WHAT??

After more than a decade of producing billet engine blocks for the VR38 platform, we can officially disclose something we’ve intentionally kept proprietary, until now.

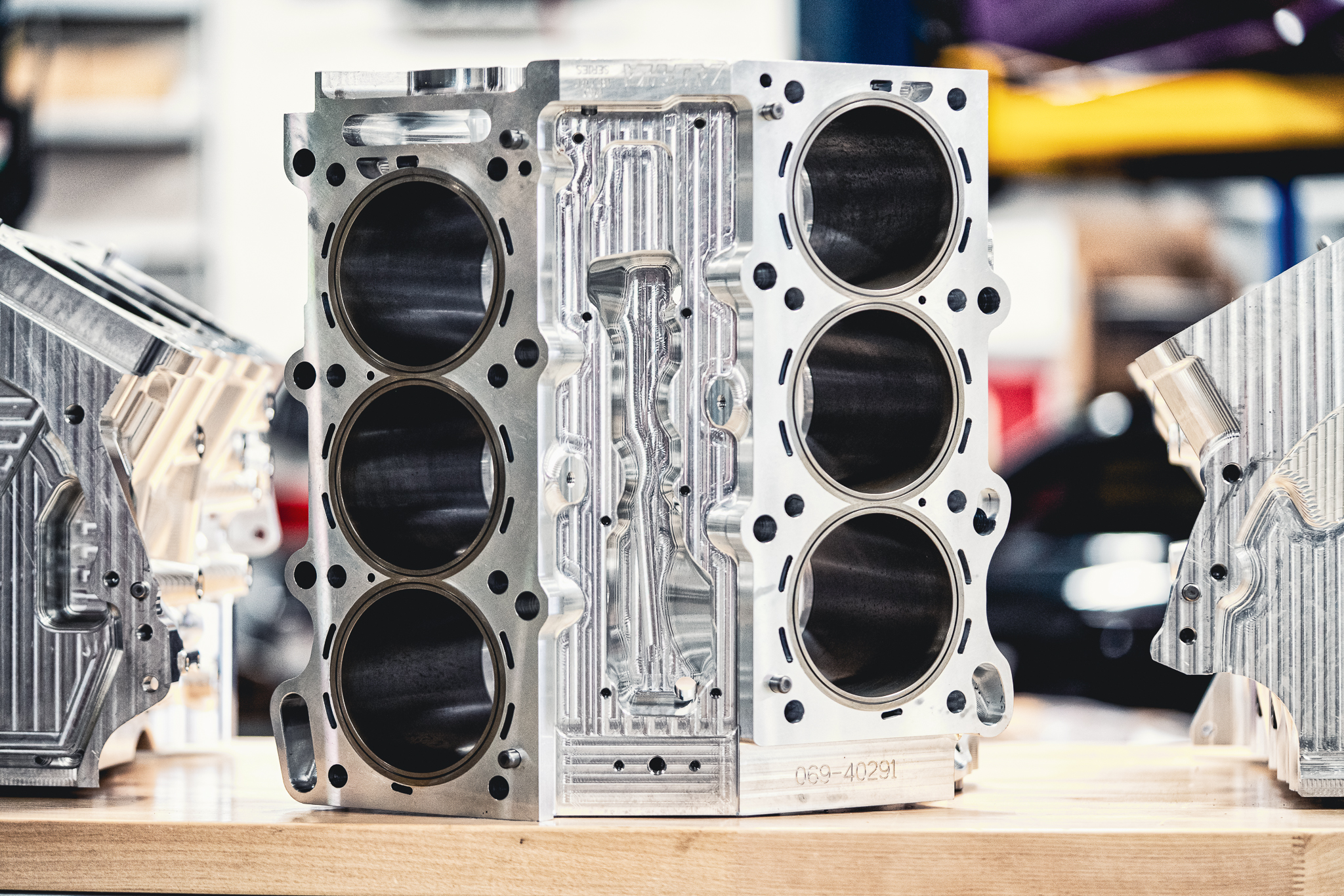

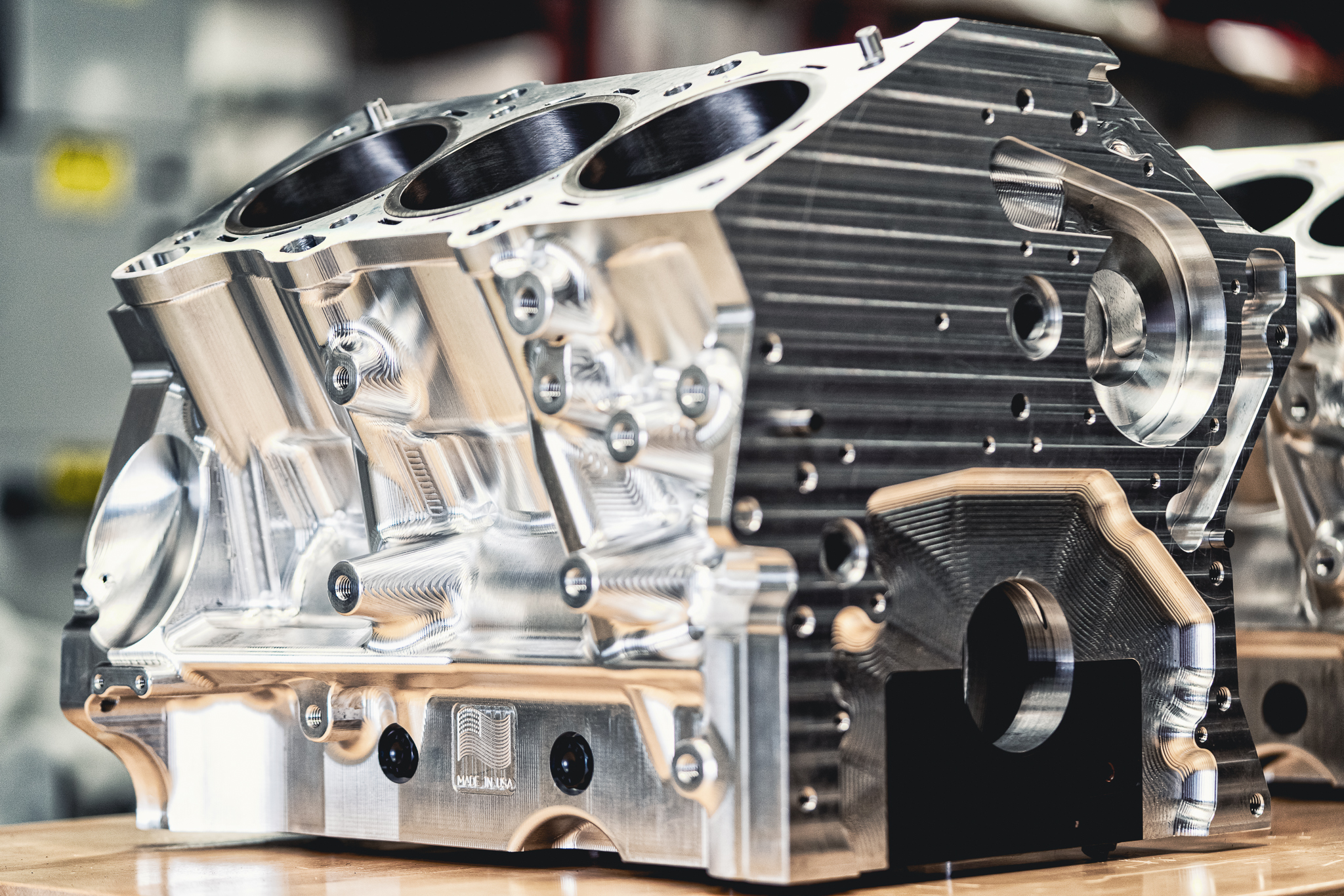

The AMS VR38 Pro Series Billet Block is machined from aerospace-grade 2219-T852 aluminum billet, and it always has been.

We chose early on to let real-world results speak for themselves. As more billet VR38 blocks have entered the market, we think it’s the right time to explain what actually makes our block different, at an engineering level.

The AMS VR38 Billet Block is made of WHAT??

If you’ve never heard of 2219 aluminum, don’t feel bad. It’s a fairly niche alloy and it’s not something you typically see advertised in automotive or motorsports parts.

2219 is an aerospace-grade, copper-bearing aluminum alloy that was not developed for ease of machining, low cost, or mass production. It was developed for critical structural applications where parts are exposed to sustained load, extreme temperature swings, and long service life requirements.

Historically, 2219 has been used extensively by NASA and aerospace manufacturers in applications such as:

- Rocket fuel and oxidizer tanks

- Cryogenic and high-pressure vessels

- Structural bulkheads and framing near propulsion systems

- Components subjected to repeated thermal cycling and vibration

One of the most famous examples is its use in launch vehicles like the Saturn V, where 2219 aluminum was trusted for large structural and pressure-containing components that absolutely could not deform, crack, or fail. These parts had to survive massive loads, extreme vibration, and temperature swings ranging from cryogenic to combustion-adjacent heat.

The common thread across these applications is simple: failure was not an option, and dimensional stability over time mattered more than anything else.

Why material history and alloy choice matter in a VR38 block

At extreme power levels, a VR38 engine block is no longer just an engine component. Functionally, it becomes:

- A pressure vessel

- A structural frame for the rotating assembly

- A component subjected to continuous thermal cycling

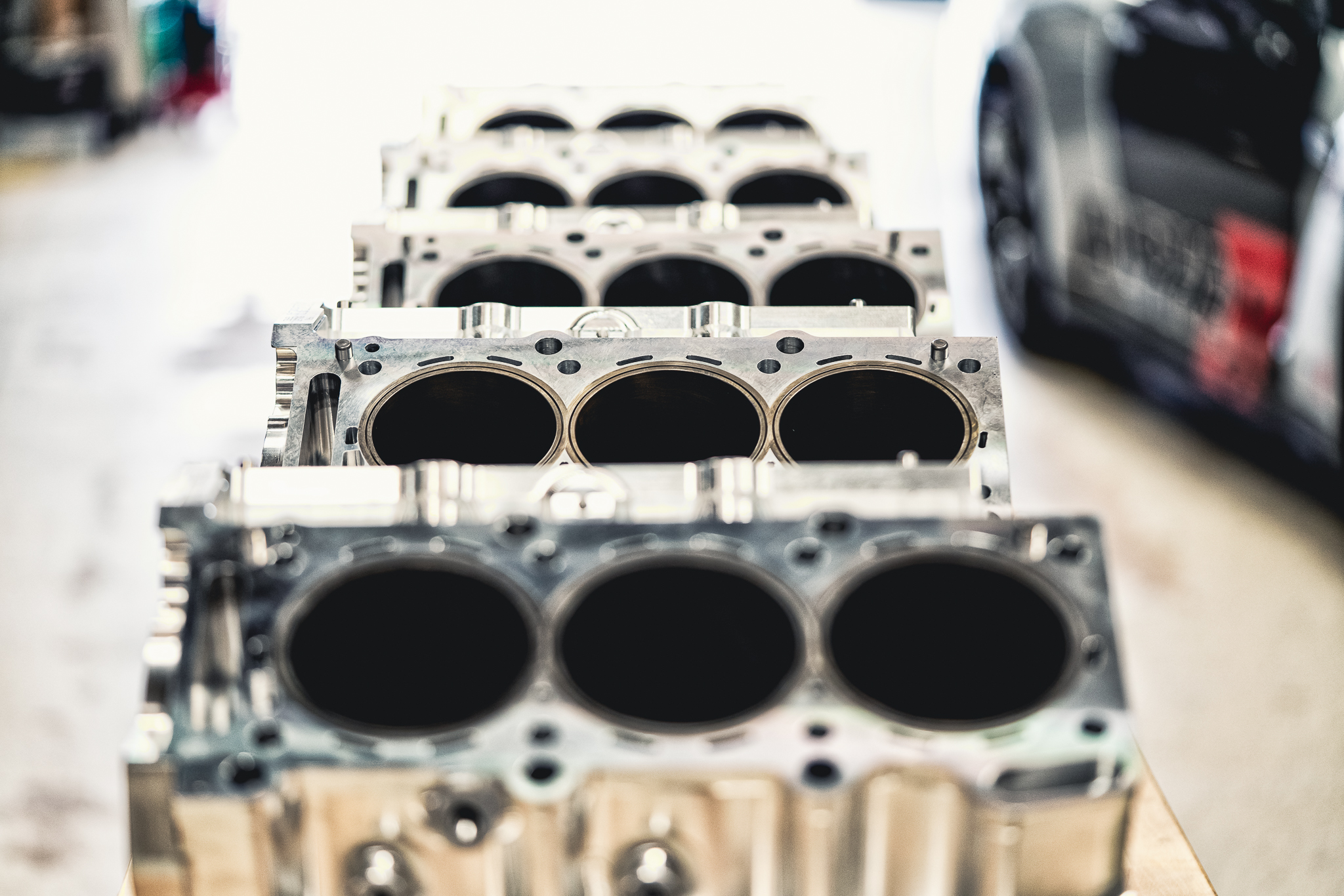

High-boost, high-power VR38 engines live under sustained cylinder pressure, heavy crankshaft and main bearing loading, and constant heat soak. In that environment, the block must maintain bore geometry, main tunnel alignment, and head gasket sealing over time. This is not about surviving short dyno pulls. It is about holding shape under heat, load, and repetition.

Those demands are far closer to aerospace structural and pressure-vessel applications than they are to typical automotive castings or general-purpose billet parts.

That is exactly the type of environment 2219 aluminum was developed for. As a copper-bearing, aerospace-grade alloy, 2219 was designed to retain strength at elevated temperatures, resist thermal fatigue, and maintain dimensional stability under sustained load. It was never intended to be inexpensive or easy to machine. It was intended to be reliable when failure is not an option.

This is why AMS Performance selected 2219-T852 from the very beginning. Compared to more common billet materials like 6061 or 7075, 2219 offers significantly better strength retention as temperatures rise, improved resistance to long-term thermal fatigue, and greater dimensional stability in high-heat, high-pressure environments.

In a VR38 billet block, that translates directly to more stable cylinder bores, better main bearing alignment, and longer service life at extreme power levels. Choosing 2219-T852 increases material cost, machining time, and production complexity, but it allows the block to behave the way it needs to behave once the engine is pushed far beyond OEM intent.

The objective was never to build the easiest billet block to manufacture. The objective was to build the most stable and durable foundation possible for extreme VR38 engines, and this material choice has proven itself quietly and consistently for more than a decade.

Main cap material matters just as much

Material selection does not stop at the block itself.

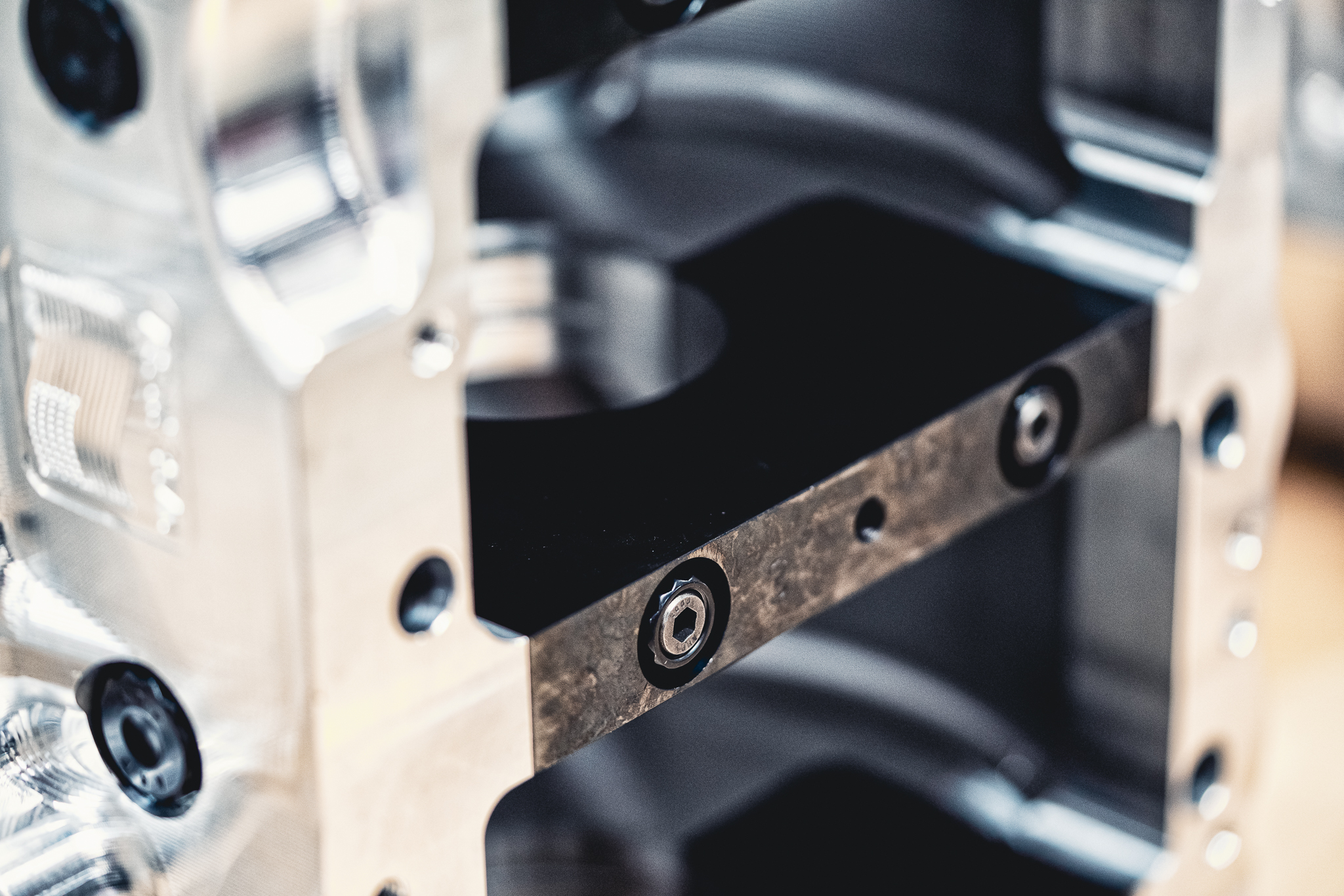

Our Pro Series Billet Block uses 4140 chromoly steel main caps, not aluminum.

Many billet blocks on the market rely on 7075 aluminum girdles or main structures. While aluminum girdles may look shiny and impressive, they cannot offer the same rigidity, fatigue resistance, or long-term stability as a proper steel main cap with splayed bolt construction under extreme crankshaft loading.

4140 steel provides:

- Far higher stiffness and strength under load

- Better resistance to cap walk and main tunnel distortion

- Improved durability under repeated high-torque cycles

At extreme power levels, crankshaft control and main tunnel stability are critical. Using steel where steel belongs is a deliberate engineering choice, not a styling decision.

Manufacturing origin matters right now

You’ve likely seen pricing increase across the industry as tariffs and overseas sourcing costs continue to affect manufacturers relying on imported billet material or fully machined blocks from China.

The AMS VR38 Pro Series Billet Block has always been manufactured entirely in the United States. That includes domestic sourcing of billet material, and American machining. Because our process has never depended on overseas supply chains, recent tariff-driven price increases have not changed how we build or support this product.

In the current market, that makes the AMS billet block more competitive than ever. When you combine proven durability, aerospace-grade materials, steel main caps, and fully domestic manufacturing, it becomes an easy choice for anyone building a serious VR38 engine.

Proven over time

Our billet blocks have been used for years in some of the highest-output VR38 engines in the world, including long-term development engines and competition vehicles that see repeated teardown and inspection. Our block was used in the first ever 6 second GTR, and continues to this day to be utilized by more 6 second VR38 builds than anything else out on the market. The AMS billet block is the definitive choice for 3000+ WHP builds.

The durability difference shows up after seasons of use, not just on a single dyno sheet. 2219 is one of the few 2000 series aluminum materials which are easily repairable, allowing for welding with minimal risk of cracking, showcasing the AMS Billet Block’s exemplary serviceability. Material behavior under real operating conditions is what separates parts that survive from parts that simply look good on paper.

We’re proud of this block, and the history of achievement it has been able to produce for our customers. We’re also happy to now finally explain why it performs the way it does.

By utilizing top tier materials like our 2219-T852 aluminum billet block with 4140 steel main caps, AMS Performance continues to raise the bar for what a true extreme-duty VR38 billet block should be.

While everyone else is content just to be able to use the “billet” buzzword, we’re making real engineering decisions where it actually matters.